Motor timings manual

Disassamble the engine so you will have a crankcase filled with a crankshaft, piston, rod and sleeve.

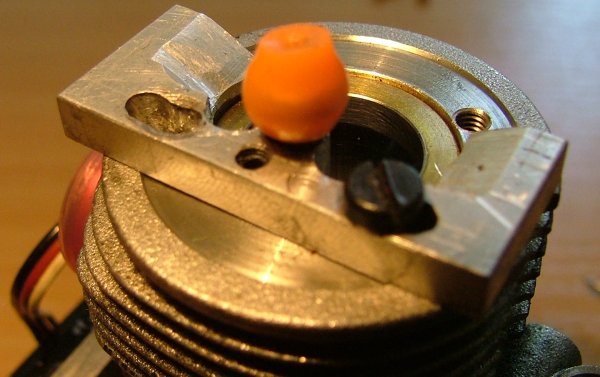

Mount the piston stopper with a bolt from the head, notice the round end tip to prevent damage (scratxhes) to the piston.

Next to the long screw there is a small rubb screw, ths screw has to be tighten to secure the sleeve.

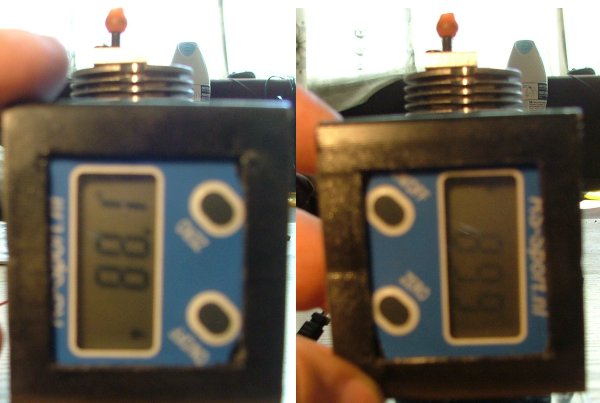

Mount the engine in the stand with the lights. Turn the piston stopper compleetly in to push the piston to BDC, mount the angle meter and set it to "0". Then turn the piston stopper out until the piston and so teh angle meter is at arround 90 degrees.

Turn the meter in both directions to the stopper so you can see the differences. Be sure the meter is not tightened to hard on the crankshaft so you can use some force to rotate the meter. Be sure in both ways it is almost showing the same.

Now the meter is calibrated.

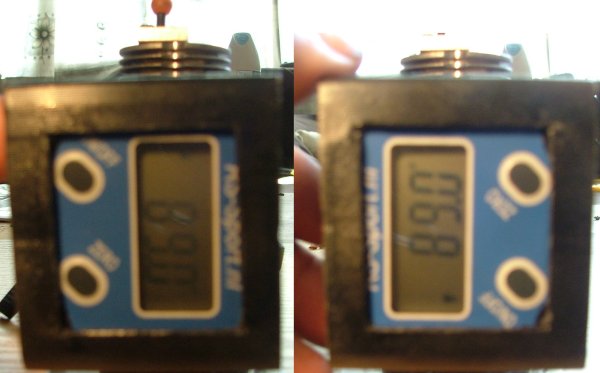

With a slight force on the meter rotated against the piston stopper find the spot where the crankshaft is closing the gap showing light:

(here on the right side in the hole the moment of opening a small line of light)

Again rotate the meter in both directions against the piston stopper.

If there is a small difference in reading calculate the average in between them. Timings are mostly rounded at full numbers and sometimes a half.

Do this again for the closing moment of the crankshaft

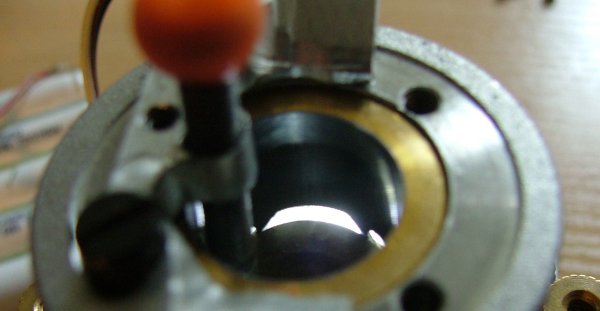

And the intake:

Some models have 2 timings on the intake ports. Still using the light from under in the crankcase.

And the exhaust with a different light pushed in the rear.:

Now you have all numbers of all timings